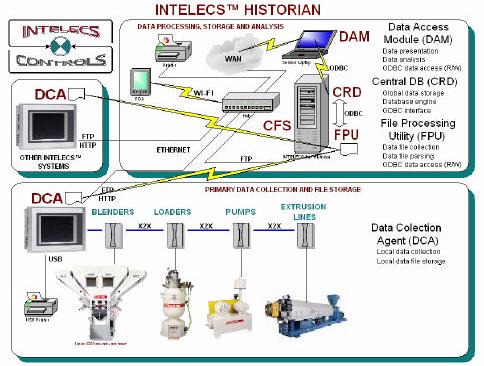

Consistent regular data collection creates a material foundation for Product Quality Management, production process optimization and Predictive Maintenance practice. INTELECS™ HISTORIAN includes distributed components working together via Ethernet network. The primary data collection performed by each controller ensures superior data quality and resolution. The powerful and robust Database Engine makes data available to any ODBC-compliant client such as Microsoft Excel Data Access Module (DAM) included in this solution.

DATA COLLECTION AGENT (DCA) IN EVERY CONTROLLER

The closer the Data Collection Agent (DCA) to the process the better. INTELECS™ HISTORIAN performs primary data collection at the controller level. The sampling rate of data collection depends on the task class in which the DCA is placed. It can be as low as 1 ms if high frequency changes need to be reflected in the collected data. The DCA stores data samples in the historical object in the controller’s memory. When the historical object is filled with data the agent creates a CSV file on the flash drive of the controller. The file name generated by the DCA indicates the type of data collection (batch blender log, extrusion line data recording, etc.) and includes the date/time stamp. Each file uniquely identifies the controller and the blender (or extrusion line) the recorded information is from. The file remains on the flash drive until it’s discovered and moved to the Central File Storage location by the central File Processing Utility (FPU) running on one of the computers with FTP access to the flash drives of the controllers. The capacity of the flash drive of each controller (typically, 64MB) is enough to keep the historical files for many hours if FPU is temporarily stopped.

FILE PROCESSING UTILITY (FPU - “SPIDER”)

The File Processing Utility (FPU) is a computer program responsible for collecting the historical files from controllers, extracting data from the files and creating data records in the Central Relational Database (CRD). The FPU is driven by the XML configuration file that specifies FTP servers, local and central historical file locations, user names and passwords. The FPU runs as a Scheduled Task on a computer located on the same subnet with all the controllers participating in the data collection process. It uses FTP access to controllers to examine the contents of their flash drives, determines the presence of historical files and moves those files to the Central File Storage (CFS). After all the historical files are transferred to the CFS, the FPU “parses” them, i.e. locates the data items in the text and creates the corresponding data records in the CRD. The FPU works with CRD (MySQL database) using MyODBC connector available as a freeware.

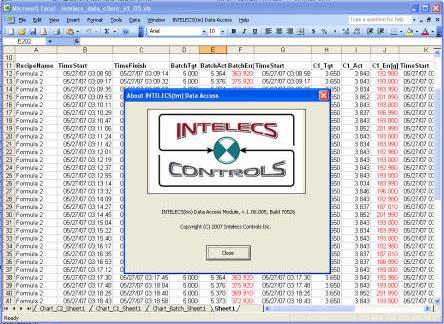

DATA ACCESS MODULE

The Data Access Module (DAM) is provided as a simple tool to support basic data requests and visualization of a query results. For example, for a Batch Blender Log the DAM automatically generates the results table that includes Recipe name, batch statistics and statistics for each component, actual weight and absolute deviation from the target for each component. The DAM works with MySQL database using MyODBC connector available as a freeware. In addition to a default standard set of supported data requests the DAM configuration can be customized upon end user’s request. A typical screen shot of Data Access Module is shown in Fig.1.