Our test results indicate that INTELECS™ BATCH implementation may result in 10-50% of throughput increase on batch blenders with pinch valve or slide gate dosing mechanisms without any changes to their mechanical designs. INTELECS™ BATCH system has been tested with a wide range of materials on blenders that use different physical principles of material dispensing. The control system consistently achieves superior throughput and accuracy working with rubber pinch valves, steel slide gates or vibrating feeders as actuators.

INTELECS™ BATCH Advantage:

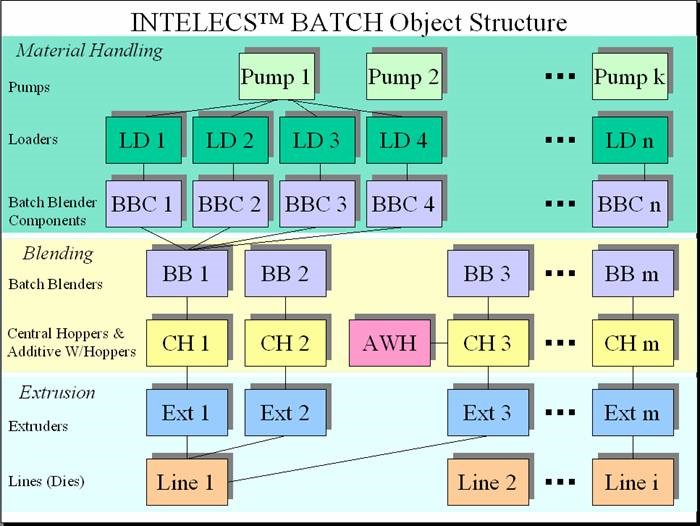

- Controls multiple blenders - up to 5 blenders, 45 loaders and 3 pumps controlled by a single INTELECS™ BATCH controller. This ability creates a significant advantage if small-size blenders in large quantities are installed in compact cells.

- A unique 3-stage dosing algorithm that allows the fastest possible delivery of components without compromising the accuracy of each component. A very flexible tuning system allows finding the optimal combination of required throughput and accuracy.

- A consistent absolute dosing accuracy of any size component within 0.5 grams of the target weight (the presence of a high-quality anti-vibration system in the blender mechanical design is assumed).

- Fully utilized networking capability: INTELECS™ BATCH system is an FTP server, web server and TCP/IP capable device. Web server is normally configured for control and monitoring of both Blending and Loading systems via a "thin" client (browser).

- Built-in INTELECS™ Historian logging all batch blender statistics to the local Flash Memory card for the consequent transfer to a relational database.

- INTELECS™ BATCH is an OPC server and can communicate with many SCADA packages that have OPC client interfaces.

- Cost-effective "OFF THE SHELF" hardware solution including a powerful central controller with a very fast distributed configurable I/O system.

- The system code is a combination of ANSI C and Automation Basic easily transferable to virtually any hardware platform.

- INTELECS™ BATCH is a control system that is "ready" for Multilayer (up to 9 layers) Extrusion Line control. The system determines extruder throughput directly from Batch Blending algorithm that makes it a much more cost-effective than "loss-in-weight" systems offered by a number of competitors.

- 2.5 years in the making and troubleshooting that resulted in about 80 incremental improvement releases. 50+ installations including single and multiple Blender control systems with or without Vacuum Loading option and several Multilayer Extrusion Line packages